AI Buyer

AI Buyer notifies you exactly when and how much to buy for procurement. It uses complex algorithms to calculate "real" lead time by factoring in holidays and working days for your company and supplier. You can even specify how many days/shifts you want product stored before being consumed. This can help in saving warehouse space and overall cost. Here's how it works:

Information Processing:

AI Buyer uses information imported from your current system or manually entered items to process its accurate purchase requirements. Imported information can be downloaded directly from your system via ODBC as read-only, meaning no data would be updated in your system. Information can also be imported from excel. Once imported once, you can setup AI Buyer to import all data automatically with one click.

AI Buyer™ - AI Report

AI Buyer will run an AI Report when computing your requirements which informs you when and how much to buy at the selected method (Lowest Quantity, Cheapest Price or Best Price) in detail. There is also a summary report printed along with it any notable missing information needed such as parts without pricing when using the best price/lowest price method or primary suppliers without any holidays/working days set (to compute accurate lead times)

Analyzing the AI Report:

-

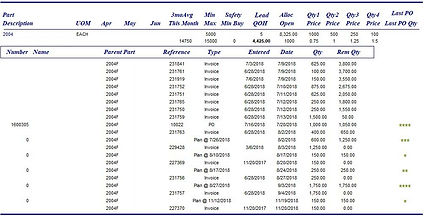

The above report is ran under "Lowest Quantity" method meaning it would buy (plan) at the lowest possible quantity

-

Top banner will display info such as part info, 3 month usages, on hand quantity, lead time, min/max, safety stock, minimum buy and the current supplier prices.

-

Report will list all open supplier POs and demand (Invoice or Workorder) for the day/shift. Types would be:

-

PO for any open purchase orders

-

Invoice for any open invoices/releases

-

Workorder for any open jobs

-

Forecast demand if forecast is enabled

-

-

The report will advise you when and how much to buy with a "Plan" entry along with date to purchase (Plan @1/1/2099) and date it will arrive (Date field)

-

The AI Report shows you demand due date, supplier PO arrive date or Plan arrive date under the "Date" field.

-

Report will calculate the remaining balance (Rem Qty) after it will be bought or consumed (Plus or minus) down the list

-

Starts off with first line plus QOH (quantity on hand)

-

Remaining balance will never go below 0 or safety stock meaning you should always have inventory available when needed

-

-

The holidays and working days for company and supplier are computed into the date required and date to purchase

-

If a supplier has a holiday in between the lead time, that lead time will increase by that extra holiday. For example a 5 day lead time will turn into a 6 day lead time if there is a holiday in between or a non-working day for the supplier (like weekends).

-

Product will not arrive on a holiday or a non-working day (receiving dept closed) for the company. It would arrive the day prior or until a working day is found.

-

-

The amount of days/shifts stored is computed into its required date. For example, if you want a product stored for a day, it would arrive a working day before its due. If you want a product stored for 1 shift, it would arrive a shift before its due. You can specify this in the parameters screen for all parts or in the parts list interface for each individual part.

-

The report will also have a green * next to the Planned/Open PO notifying you of the Price Rating used. 5 stars means you are buying at the cheapest price. 1 star means you are buying at the most expensive price.

Purchase Types:

There are several types of methods you can use to run your requirements

-

Lowest Quantity (Shown on above report)

-

Best Price

-

Lowest Price

Best Price:

This method buys at the best price available from the part's primary supplier while maintaining the Remaining quantity at 0 or safety stock. In other words, not over buying based on your demand. Click image to expand

Lowest Quantity:

This method buys at the lowest possible quantity based on the demand for the day. If minimum buy is enabled, it would buy at the minimum buy quantity for that part instead. Lowest quantity method can also be used when supplier requires a mixed full trailer load to get the cheapest price. You can enable Trailer Buy and AI Buyer will compute requirements and consolidate parts into trailer(s). See below

Lowest Price:

This method also buys at the best price available but will consolidate the last recommended buy quantity into its previous one to get the best price. This option though may take up more warehouse space while also maintaining the Remaining quantity at 0 or safety stock quantity. Click image to expand

Force buy at more expensive price:

Sometimes it may need to buy at a more expensive price if it needs to. The ending remaining balance should be 0 or the safety stock just like in this example below.

Trailer Buy:

AI Buyer can assign pallets to a trailer. You can specify how many pallets fit in a trailer in the parameters screen and also how many parts fit into a pallet in the parts list interface.

Trailer Summary:

This report summarizes how many part pallets will fit in a truck. This is automatically run after computing your requirements

Trailer Detail:

This report displays in detail such as how many parts will fit in a pallet and to what truck #. This is automatically run after computing your requirements

Shift Requirements:

AI Buyer can compute shift requirements. You can specify how many shifts you want product stored before being consumed. In this sample, we specified we want to store product for 1 shift before its due. We also created a holiday for 7/20. (The shift is the -# after the date)

Safety Stock:

You don't have to worry about inventory going below your safety stock by applying a safety stock to your part. As you can see calculated remaining Qty (Rem Qty) will never go below the safety stock

Confirm POs:

Once AI Buyer has computed requirements, you can now confirm the POs to acknowledge which out of the list you want to generate POs for. Once confirmed, PO's will then be created.

Purchasing System:

This interface allows you to edit any POs that were created when confirming POs or create new POs. You can also email / export the PO. Optionally this interface allows you to also receive parts into the system with part inspection criteria when receiving along with debit memos, etc.